3D CAD / Computer Aided Design

IEE provides 3D CAD services in New Zealand and Internationally.

3D CAD is essentially a digital sculpting tool, allowing our designers to craft detailed and lifelike models of your products. From concept to creation, we bring your ideas to life with precision and innovation.

3D CAD

Computer Aided Design

IEE provides 3D CAD services in New Zealand and Internationally.

3D CAD is essentially a digital sculpting tool, allowing our designers to craft detailed and lifelike models of your products. From concept to creation, we bring your ideas to life with precision and innovation.

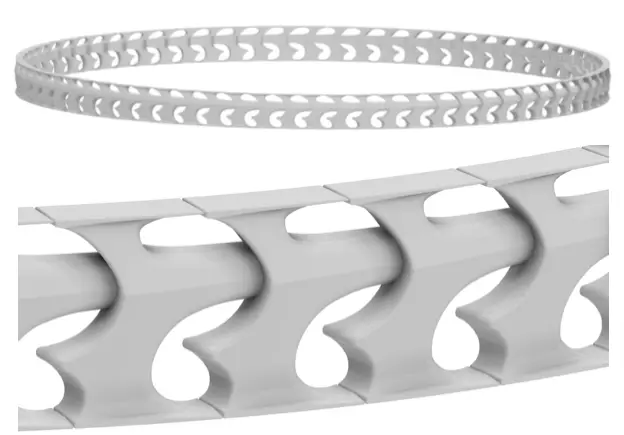

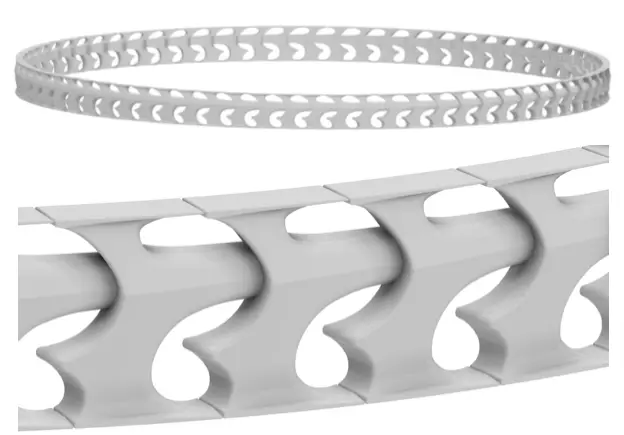

ĀTEA A RANGI - STAR COMPASS

We were bought in by Law Creative Group to take care of the 3D Modelling for the inlay pieces & Markers. 72 Stainless 3D Metal Printed pieces pattern their way around the groove of the stone beautifully. Image of completed project can be found in link below.

Ram3d - 3D Metal Printing All the Inlay Pieces & Markers

ATD Stone Mason - Fitting of all the Inlay Pieces, Markers etc

Kahu NZ - Blackhawk Helicopter / Lift Work

These are some of the other local companies that were involved with the project.

For more info check out

https://www.lawcreative.co.nz/mauao

ĀTEA A RANGI - STAR COMPASS

We were bought in by Law Creative Group to take care of the 3D Modelling for the inlay pieces & Markers. 72 Stainless 3D Metal Printed pieces pattern their way around the groove of the stone beautifully. Image of completed project can be found in link below.

Ram3d

3D Metal Printing All the Inlay Pieces & Markers

ATD Stone Mason

Fitting of all the Inlay Pieces, Markers etc

Kahu NZ

Blackhawk Helicopter / Lift Work

These are some of the other local companies that were involved with the project.

For more info check out

https://www.lawcreative.co.nz/mauao

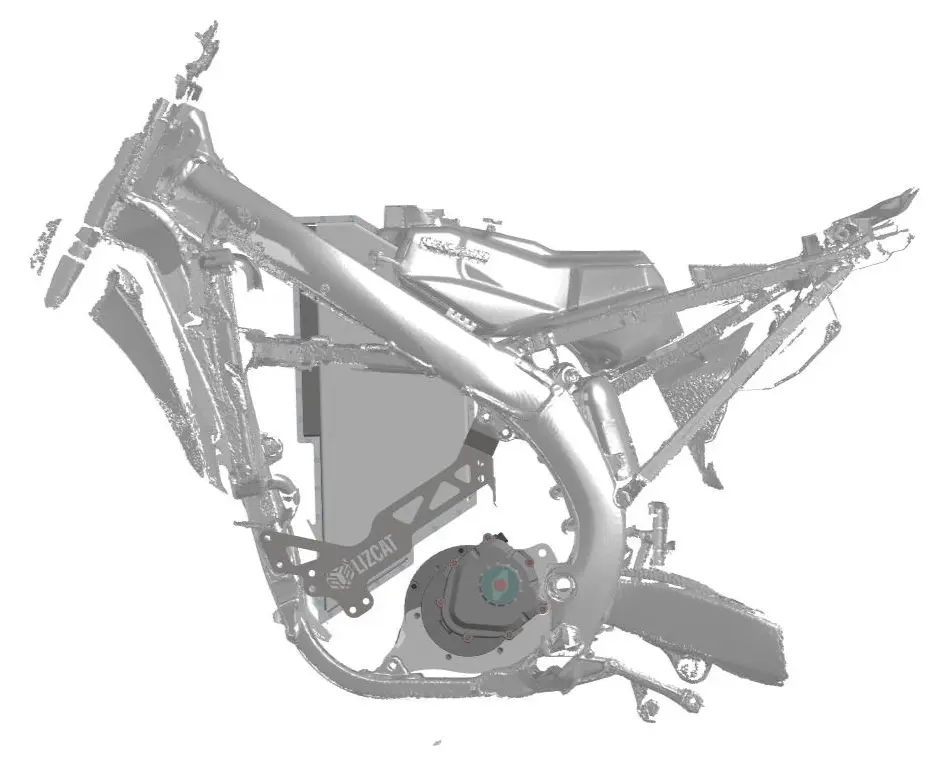

Motorbike Electric Conversions

Switzerland based company Lizcat is charging its way forward to make a huge impact into the Motocross industry around the world, as Switzerland & Europe's race tracks are rapidly being closed down due to noise and emissions. Lizcat identified there needed to be a change.

Lizcat & IEE have been working together since early 2022 to develop Electric Conversion Kits which will be available for a wide range of makes and models such as Yamaha, Kawasaki, Honda, Suzuki, KTM Etc

The Beauty of Lizcat is that the focus is totally on the conversion kit itself, Battery, Motor & Controllers. This will allow bike owners to convert the bike they already own and have it customised. The kits are aimed to be fully reversible where possible when frame sizing and constraints allow.

IEE uses 3D Scanned Motorbike Frames together with Lizcat's Custom Battery & Various Other Manufacturer CAD Data to assemble the bikes in the digital world. Once the final assembly is achieved all files are exported and the parts are manufactured.

For more info check out Lizcat - Motocross Electric

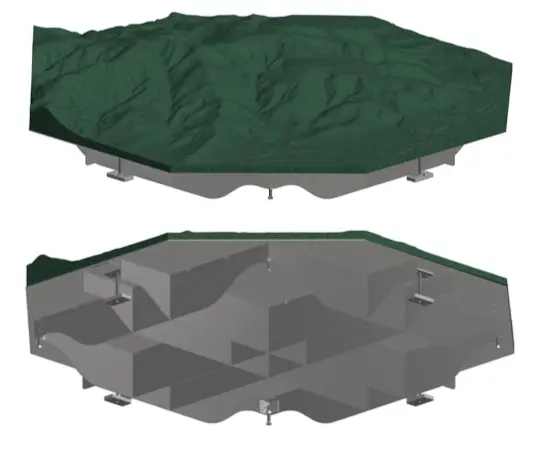

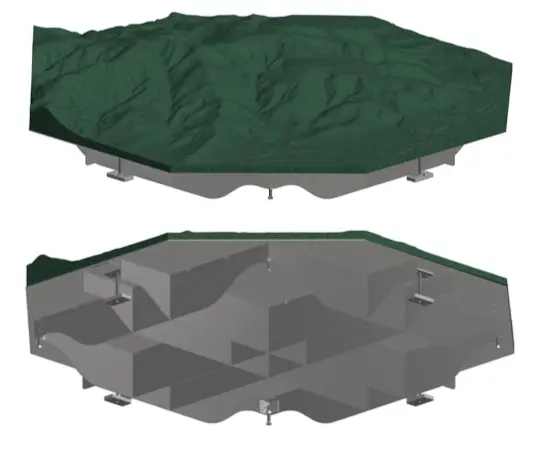

Pap Hills 3D Map

We were bought in by Law Creative Group to take care of designing the Base Frame and Map assembly.

- Using our inhouse CAD services we crafted this masterpiece

- Frame, Steel Flat Pack slotted and tabbed for quick and efficient assembly.

- 69 3D Printed Map Blocks

- Making the most of our 3D Scanning services we 3D Scanned the Granite Plinth in order to accommodate the Map edges to be parallel and have equal spacing and gaps all around.

For more info check out

https://www.lawcreative.co.nz/papamoa-hills

Pap Hills 3D Map

We were bought in by Law Creative Group to take care of designing the Base Frame and Map assembly.

- Using our inhouse CAD services we crafted this masterpiece

- Frame, Steel Flat Pack slotted and tabbed for quick and efficient assembly.

- 69 3D Printed Map Blocks

- Making the most of our 3D Scanning services we 3D Scanned the Granite Plinth in order to accommodate the Map edges to be parallel and have equal spacing and gaps all around.

For more info check out

https://www.lawcreative.co.nz/papamoa-hills

Transport Ramps

One of many projects for East Coast Heavy Diesel

The Requirements

- 3D Assembly Model

- Check all components worked together

-Ram mounting location and stroke was correct for the mounting brackets

- Enough travel in the ramps when folded down if parked awkwardly

- DXF Files for laser cutting plates

- Technical Drawings for fabrication

- Machining Technical Drawings

- BOM

Transport Ramps

One of many projects for East Coast Heavy Diesel

The Requirements

- 3D Assembly Model

- Check all components worked together

-Ram mounting location and stroke was correct for the mounting brackets

- Enough travel in the ramps when folded down if parked awkwardly

- DXF Files for laser cutting plates

- Technical Drawings for fabrication

- Machining Technical Drawings

- BOM

Fabrication + Quality Control Jig

IEE produces aftermarket Electronic Throttle Pedal units for a range of Nissan Chassis, which required the electronic pedal base unit and the original cable pedal to be 3D Scanned. The two pedals are overlaid using the mounting flange and bolt hole axis in CAD.

Once aligned we reverse engineer the original pedal rod to meet up with the New Electronic Pedal Rod.

The new pedal rods are CNC bent

The Rods are then QC checked with our Inspection Jig to validate they are within the tolerance range.

Using the same jig we can fabricate and weld the Pedal Rod to the other half of the assembly and do a second QC check.

Welding, painting & final assembly can then take place.

Fabrication + Quality Control Jig

IEE produces aftermarket Electronic Throttle Pedal units for a range of Nissan Chassis, which required the electronic pedal base unit and the original cable pedal to be 3D Scanned. The two pedals are overlaid using the mounting flange and bolt hole axis in CAD.

Once aligned we reverse engineer the original pedal rod to meet up with the New Electronic Pedal Rod.

The new pedal rods are CNC bent

The Rods are then QC checked with our Inspection Jig to validate they are within the tolerance range.

Using the same jig we can fabricate and weld the Pedal Rod to the other half of the assembly and do a second QC check.

Welding, painting & final assembly can then take place.

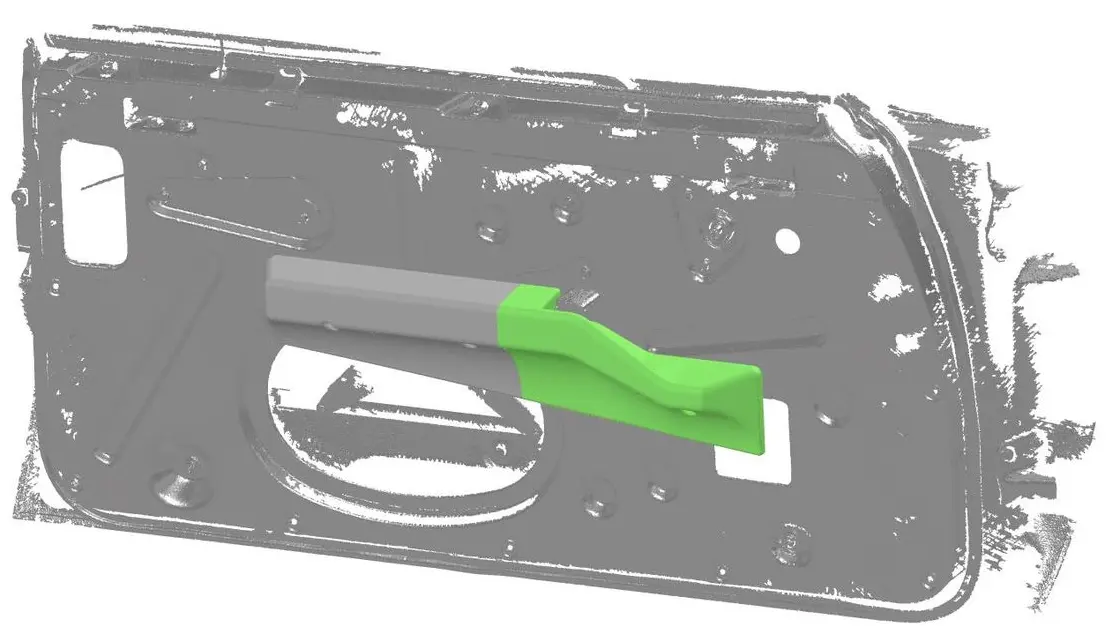

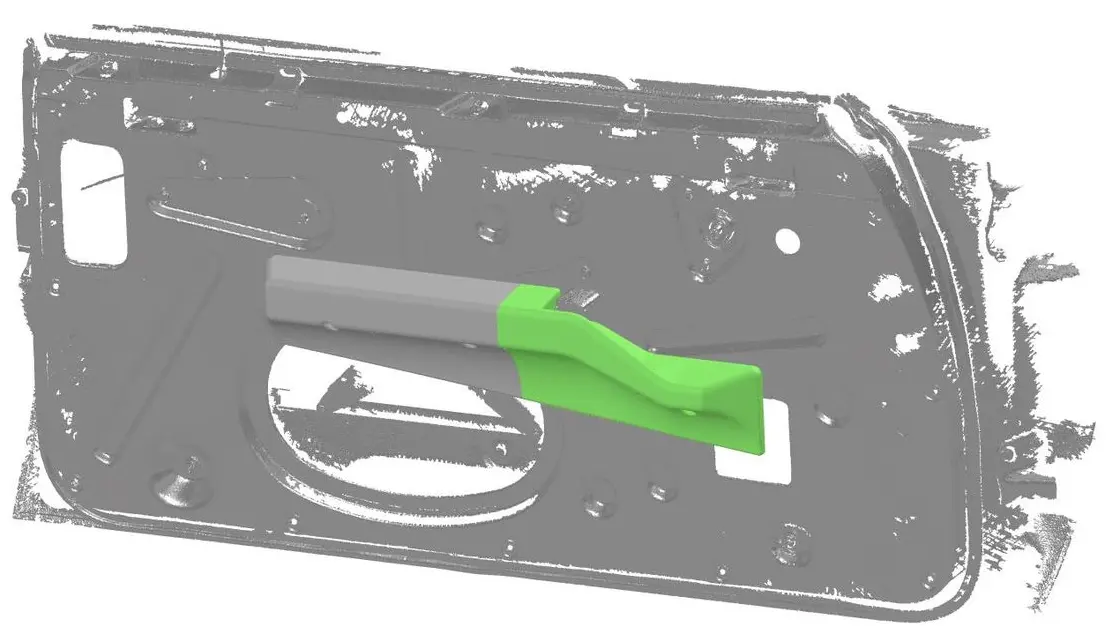

Custom Arm Rest

This client wanted a modified replacement arm rest for a HQ-WB Holden.

We 3D Scanned the original door card arm rest and door structure itself to make sure we could perfectly align the bolt holes.

From this we were then able to craft the desired product that the customer had envisioned and 3D printed the 2 part assembly.

All 3D printing was achieved in-house.

Custom Arm Rest

This client wanted a modified replacement arm rest for a HQ-WB Holden.

We 3D Scanned the original door card arm rest and door structure itself to make sure we could perfectly align the bolt holes.

From this we were then able to craft the desired product that the customer had envisioned and 3D printed the 2 part assembly.

All 3D printing was achieved in-house.

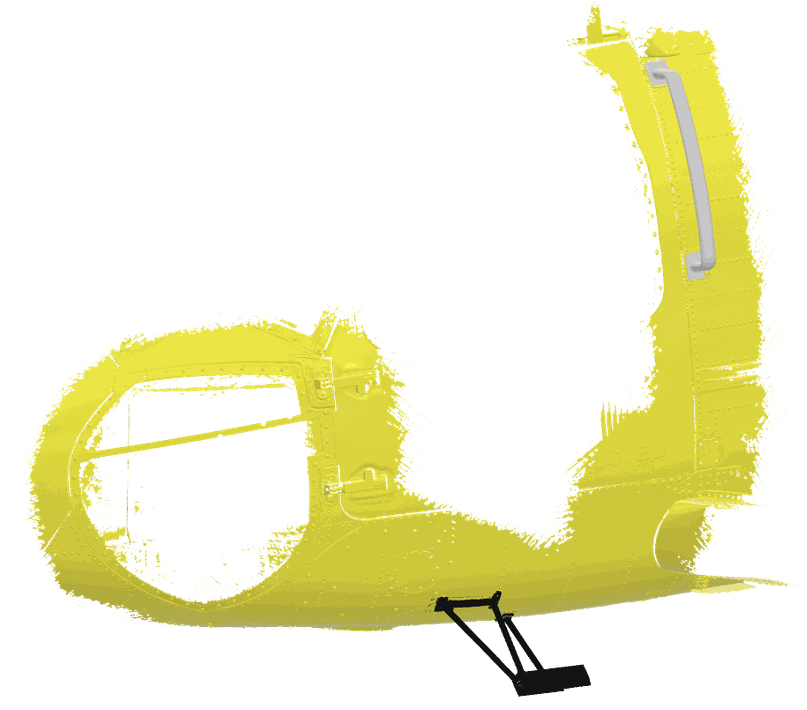

Aviation Components

Design Validation

Kahu NZ required additional exterior equipment to assist during jobs, for better sight to the underside of the Black Hawk, as well as better pilot access to the cockpit via a new step and handle.

The Step pictured was the fabricated concept to test feel and load. Fabrication of the Step consisted of using a 3D Printed Jig to replicate the Black Hawks body shape and bolt pattern.

Aviation Components

Design Validation

Kahu NZ required additional exterior equipment to assist during jobs, for better sight to the underside of the Black Hawk, as well as better pilot access to the cockpit via a new step and handle.

The Step pictured was the fabricated concept to test feel and load. Fabrication of the Step consisted of using a 3D Printed Jig to replicate the Black Hawks body shape and bolt pattern.