3D Printing

Our 3D Printing Service started in 2019.

We provide a range of in-house 3D Printing solutions to cater to your specific requirements; from prototyping to end use products.

A little bit about the types of printing technology we use can be found below, followed by some use cases and 3D printing info.

We recommend giving us a call or email for more info about the technologies and materials we use, to help establish the most suitable solution for your specific application and requirements.

3D Printing

Our 3D Printing Service started in 2019.

We provide a range of in-house 3D Printing solutions to cater to your specific requirements; from prototyping to end use products.

A little bit about the types of printing technology we use can be found below, followed by some use cases and 3D printing info.

We recommend giving us a call or email for more info about the technologies and materials we use, to help establish the most suitable solution for your specific application and requirements.

Powder Based Printing

Filament Based Printing

Powder-based printing, also known as powder bed fusion, utilizes a fine powder material such as plastic, metal, or ceramics. Layer by layer, a high-powered laser or electron beam selectively fuses the powder particles, creating intricate and precise three-dimensional objects. This method excels in producing durable parts with complex geometries, making it ideal for industries like aerospace, automotive, and engineering. Powder-based printing offers a wide range of materials, including metals like titanium and aluminium, as well as ceramics, providing versatility for various applications.

Resin-based printing, also called stereolithography or SLA, utilizes liquid photopolymer resin and is cured layer by layer using UV light. This method excels in producing highly detailed and smooth surfaces, making it ideal for applications requiring intricate designs and fine details. From jigs & moulds to end use parts, resin-based printing offers exceptional precision and aesthetics. With a range of materials available, including consumer grade, flexible, biocompatible resins, engineering & end use ready materials. It provides versatility for various industries, ensuring quality results for every project.

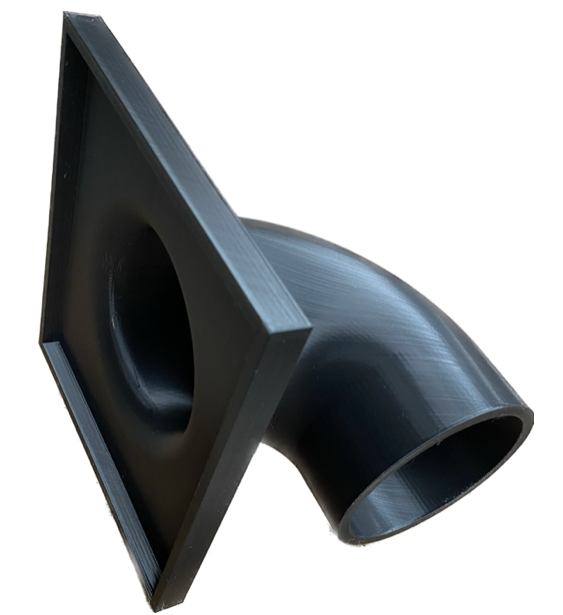

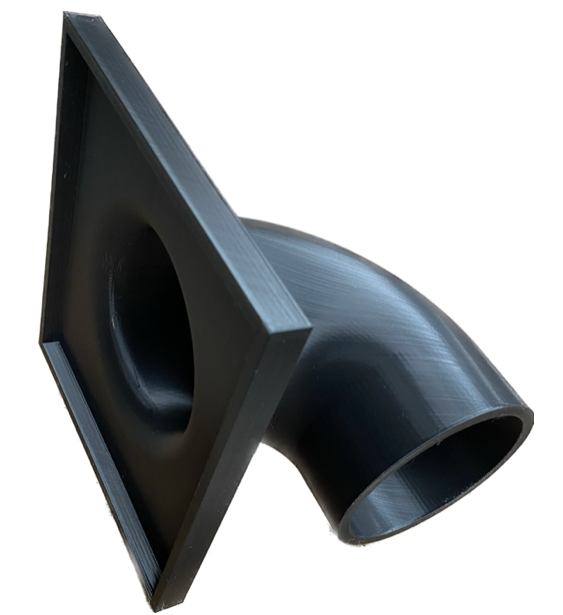

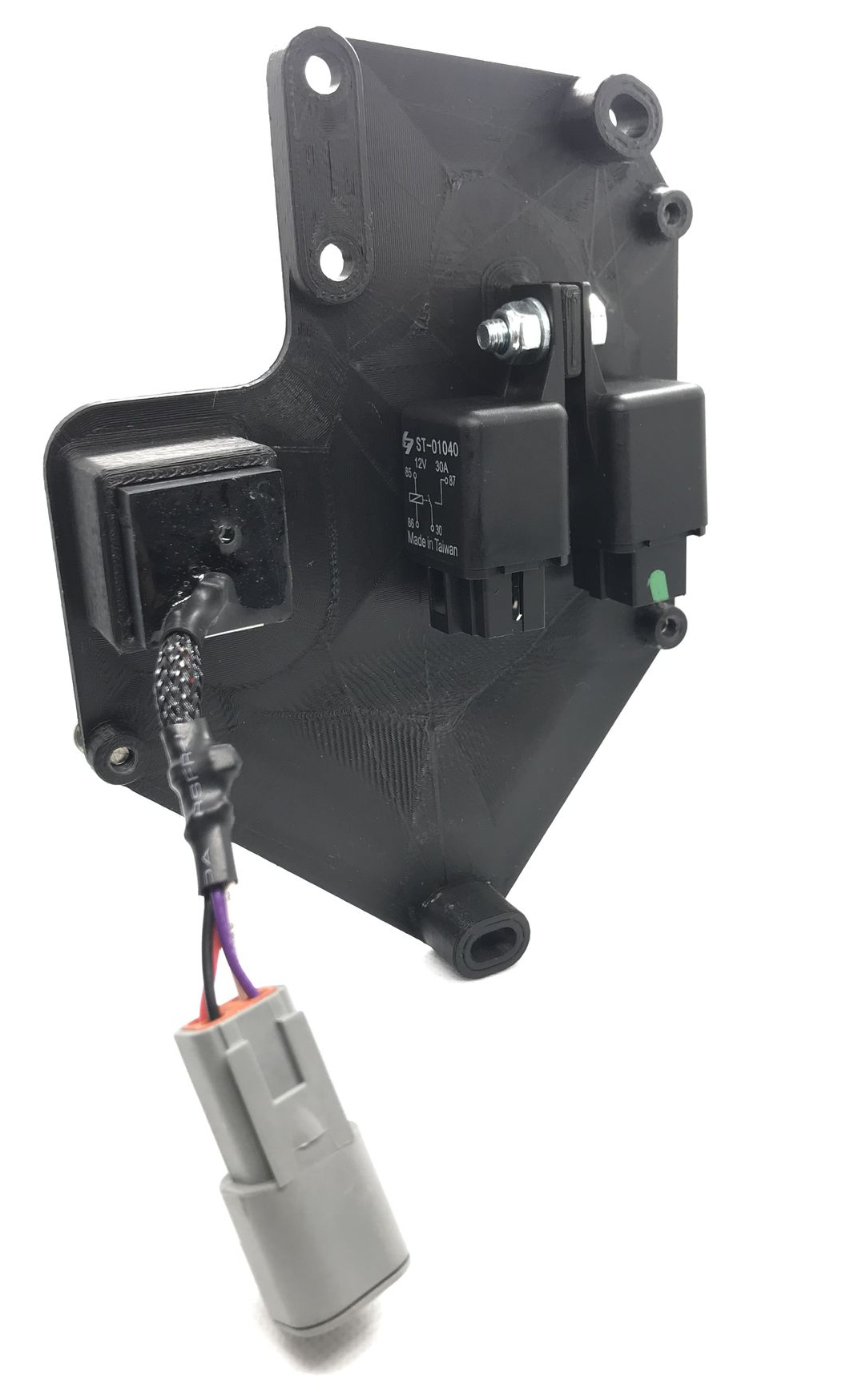

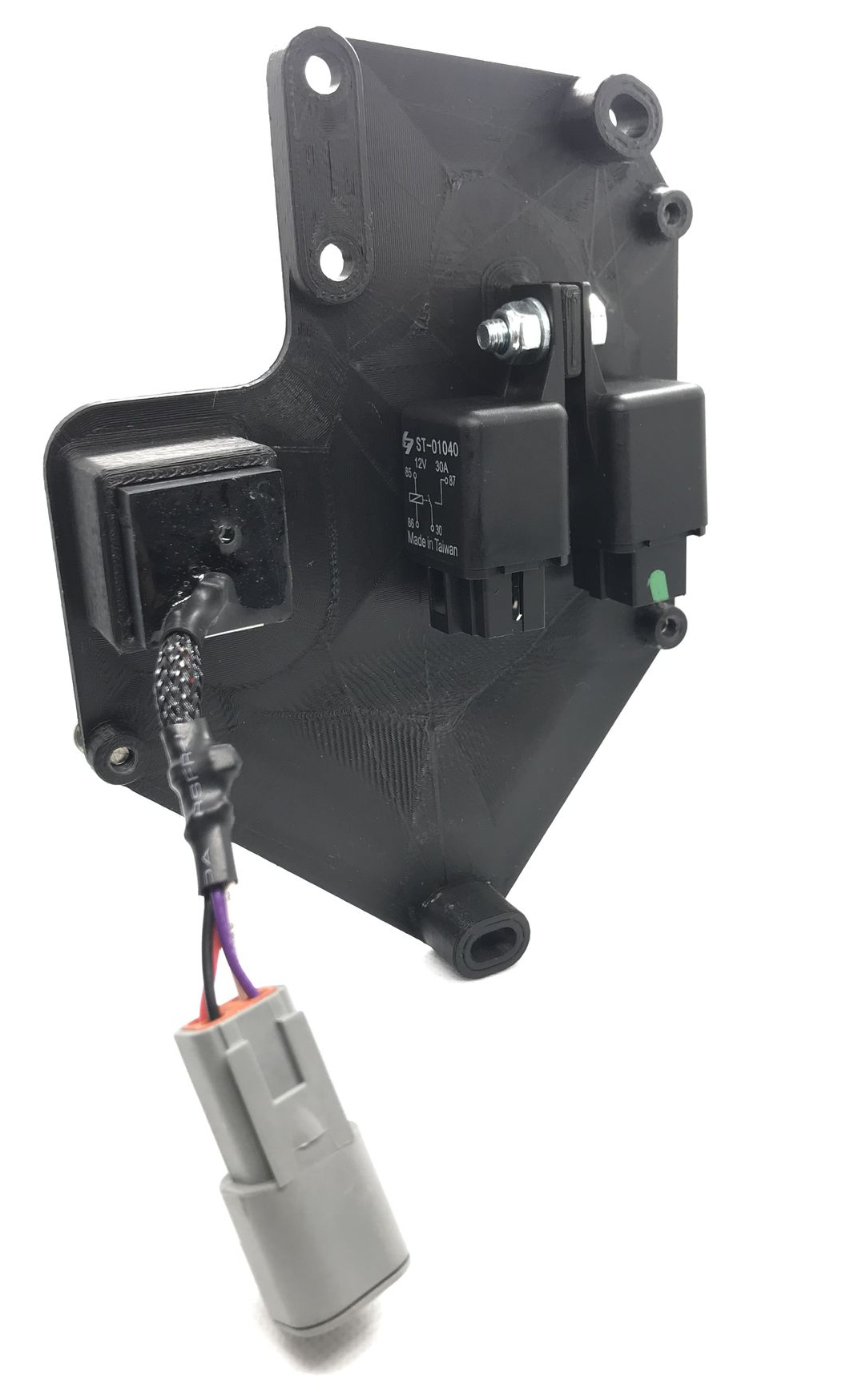

Filament-based printing is one of the most widely used 3D printing methods, known for its cost-effectiveness and versatility. It operates by feeding a roll of plastic wire (known as filament) into an extruder where it is heated and melted. The molten plastic is then precisely deposited layer by layer, building the desired object based on computer-generated designs. This method is favoured for its affordability and suitability for both prototyping and end-use parts across industries. Filament-based printing offers a variety of materials, including PLA, ABS, PETG, and more, catering to diverse project requirements.

Powder Based Printing

Resin Based 3D Printing

Filament Based Printing

Powder-based printing, also known as powder bed fusion, utilizes a fine powder material such as plastic, metal, or ceramics. Layer by layer, a high-powered laser or electron beam selectively fuses the powder particles, creating intricate and precise three-dimensional objects. This method excels in producing durable parts with complex geometries, making it ideal for industries like aerospace, automotive, and engineering. Powder-based printing offers a wide range of materials, including metals like titanium and aluminium, as well as ceramics, providing versatility for various applications.

Resin-based printing, also called stereolithography or SLA, utilizes liquid photopolymer resin and is cured layer by layer using UV light. This method excels in producing highly detailed and smooth surfaces, making it ideal for applications requiring intricate designs and fine details. From jigs & moulds to end use parts, resin-based printing offers exceptional precision and aesthetics. With a range of materials available, including consumer grade, flexible, biocompatible resins, engineering & end use ready materials. It provides versatility for various industries, ensuring quality results for every project.

Filament-based printing is one of the most widely used 3D printing methods, known for its cost-effectiveness and versatility. It operates by feeding a roll of plastic wire (known as filament) into an extruder where it is heated and melted. The molten plastic is then precisely deposited layer by layer, building the desired object based on computer-generated designs. This method is favoured for its affordability and suitability for both prototyping and end-use parts across industries. Filament-based printing offers a variety of materials, including PLA, ABS, PETG, and more, catering to diverse project requirements.

3D Print Use Cases

Why 3D Print?

Use cases for 3D Printing are endless

- Healthcare

- Automotive

- Aerospace

- Architecture

- Fashion and Jewellery

- Education

- Manufacturing

- Entertainment

- Food

Rapid Prototyping: Quickly iterate designs and bring products to market faster.

Customisation: Tailor products to individual needs and preferences.

Complexity: Create intricate geometries impossible with traditional methods.

Cost Reduction: Minimize material waste and eliminate expensive tooling.

On-Demand Production: Manufacture items as needed, reducing inventory costs.

Innovation: Explore new materials and design possibilities with ease.

Sustainability: Reduce environmental impact through localized manufacturing and reduced waste.

3D Print Use Cases

Why 3D Print?

Use cases for 3D Printing are endless

- Healthcare

- Automotive

- Aerospace

- Architecture

- Fashion and Jewellery

- Education

- Manufacturing

- Entertainment

- Food

Rapid Prototyping: Quickly iterate designs and bring products to market faster.

Customisation: Tailor products to individual needs and preferences.

Complexity: Create intricate geometries impossible with traditional methods.

Cost Reduction: Minimize material waste and eliminate expensive tooling.

On-Demand Production: Manufacture items as needed, reducing inventory costs.

Innovation: Explore new materials and design possibilities with ease.

Sustainability: Reduce environmental impact through localized manufacturing and reduced waste.

IEE 3D Printing Services

For more info, give us a call or email to discuss your next 3D Printing projects. Once we understand what the requirements are we can suggest the best printing solution & generate a quote within 48 Hours.

IEE 3D Printing Services

For more info, give us a call or email to discuss your next 3D Printing projects. Once we understand what the requirements are we can suggest the best printing solution & generate a quote within 48 Hours.