Authorised Henkel LOCTITE® Distributor

In-House Engineering & Technical Support

Shipping Across New Zealand & Australia

Find the Right LOCTITE® Resin for Your Application

Not sure where to start? Our Buyer Guide's keeps it simple.

If your new to resin 3D Printing then begin by narrowing your options based on operating temperature, Primary Property or Color - Three of the most common factors in choosing the right resin.

New To Resin (Buyer's Guide)

or Technical users wanting in depth data like tensile strength, elongation at break, Young’s modulus, or even more such as

Ageing and Enviromental Effects

- Heat Ageing

- Accelerated Weathering (UV Ageing)

- Thermal Influence On Mechanical Properties

- Chemical Resistance Industrial & Mass Soak

- Salt Spray Exposure

Head over to the LOCTITE-AM Website material selector, choose from the categories High Impact High Temp & Elastomeric and begin filtering through the displayed options.

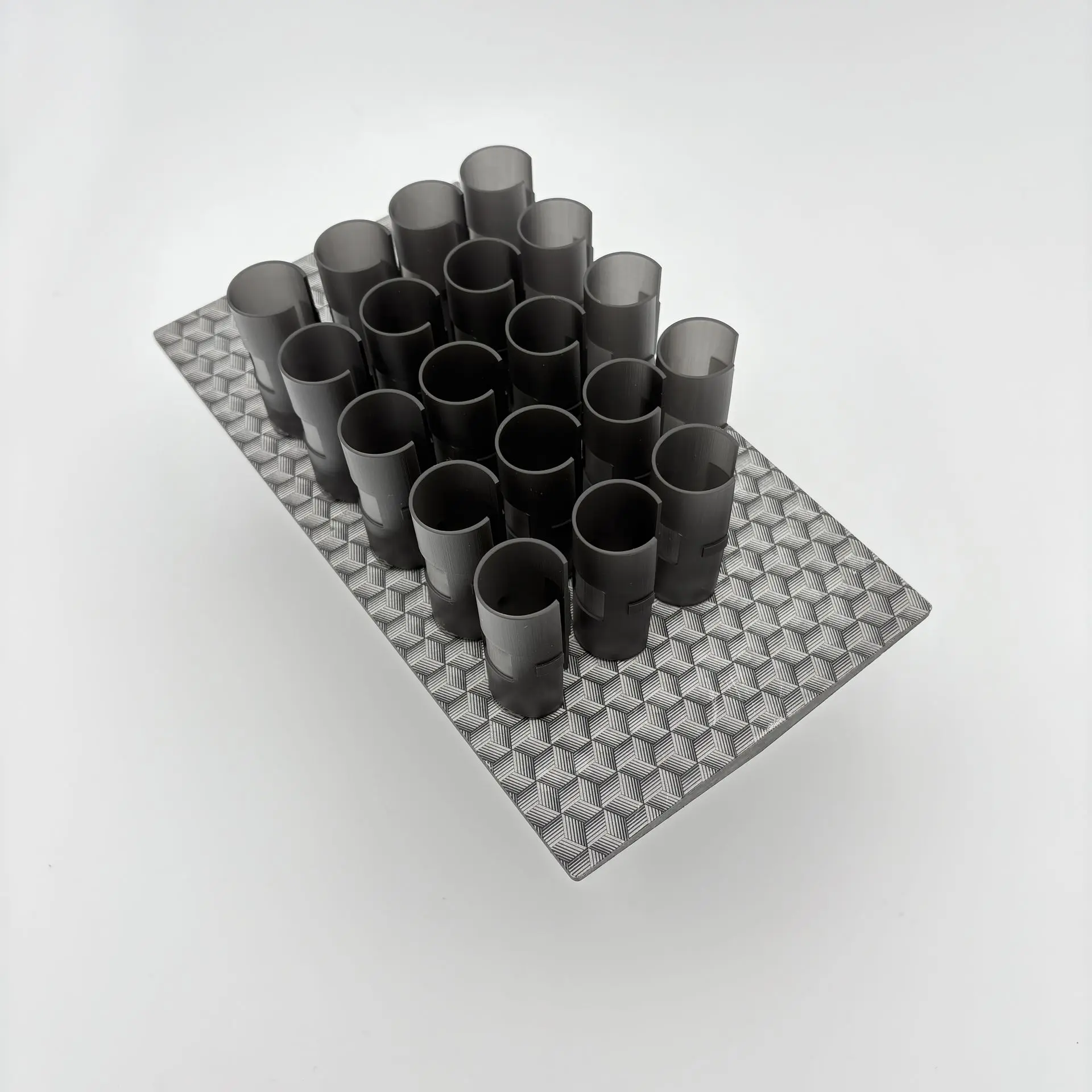

Production Grade Resin in Action

Here's a look at what real production using LOCTITE® resin looks like - from functional interior boat parts to clear lenses and housings.

Every part shown here has been printed, tested, and delivered by the IEE team using the same resins available on this site.

More Case Studies coming soon

The Engineering Advantage

LOCTITE® vs. Consumer Grade

UV Damaged PB Voxel indicator lens printed from consumer grade resin

3D Resin Printed PB Voxel indicator lens made from consumer-grade resin, yellowed after only two weeks of sunlight exposure.

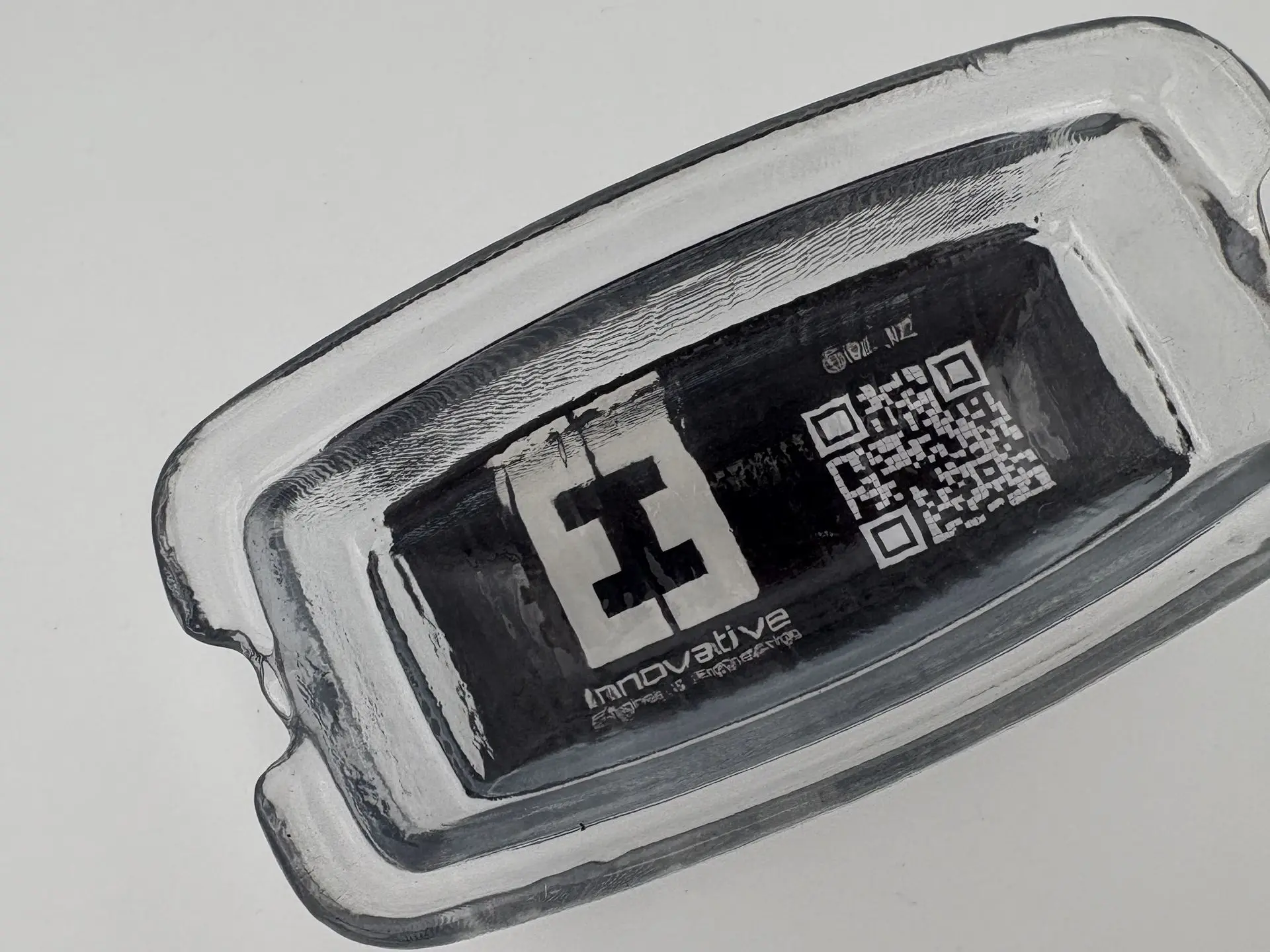

UV Stable PB Voxel Light Lense printed from LOCTITE® IND405 Clear

3D Resin Printed PB Voxel lens maintaining its clarity with no yellowing after UV exposure, ideal for long-term outdoor use.

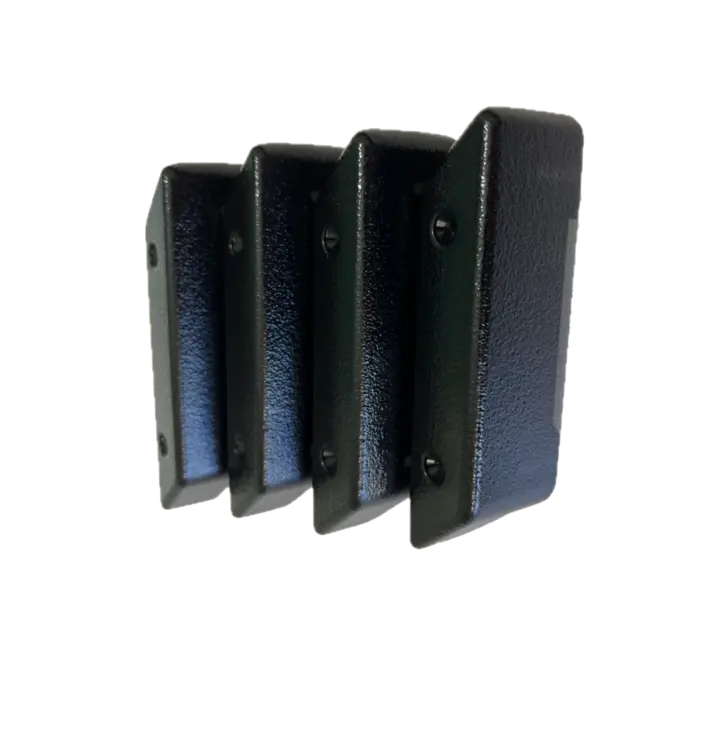

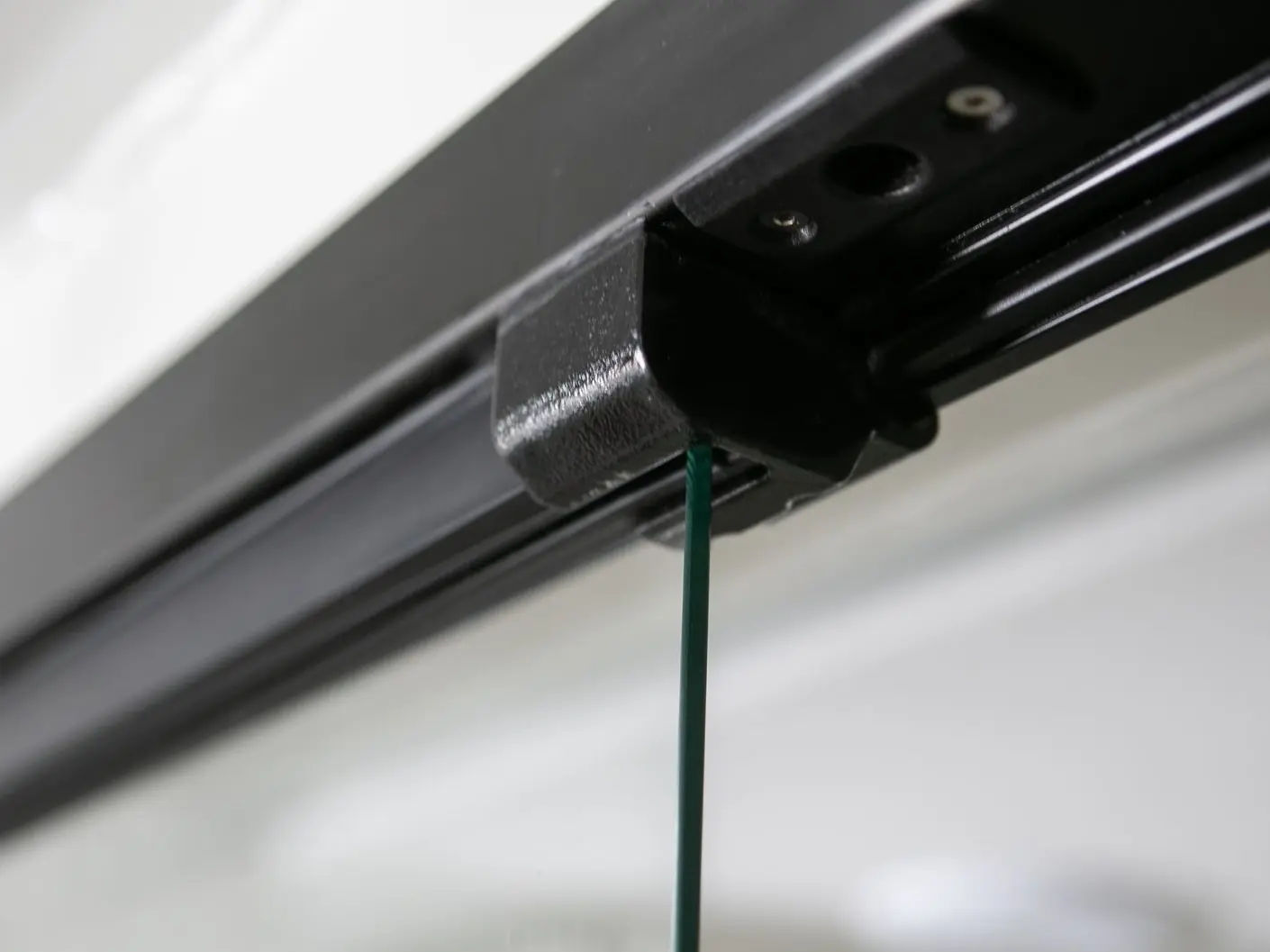

Moisture absorbtion stable window components printed from LOCTITE® IND406

Saltwater-resistant sliding window extrusion cap for marine use, printed in Henkel LOCTITE® IND 406 black.

Moisture Absorbtion instability on parts printed from consumer grade resin

Multiple resin parts printed with consumer-grade materials, swollen and cracked from sun and rain exposure.

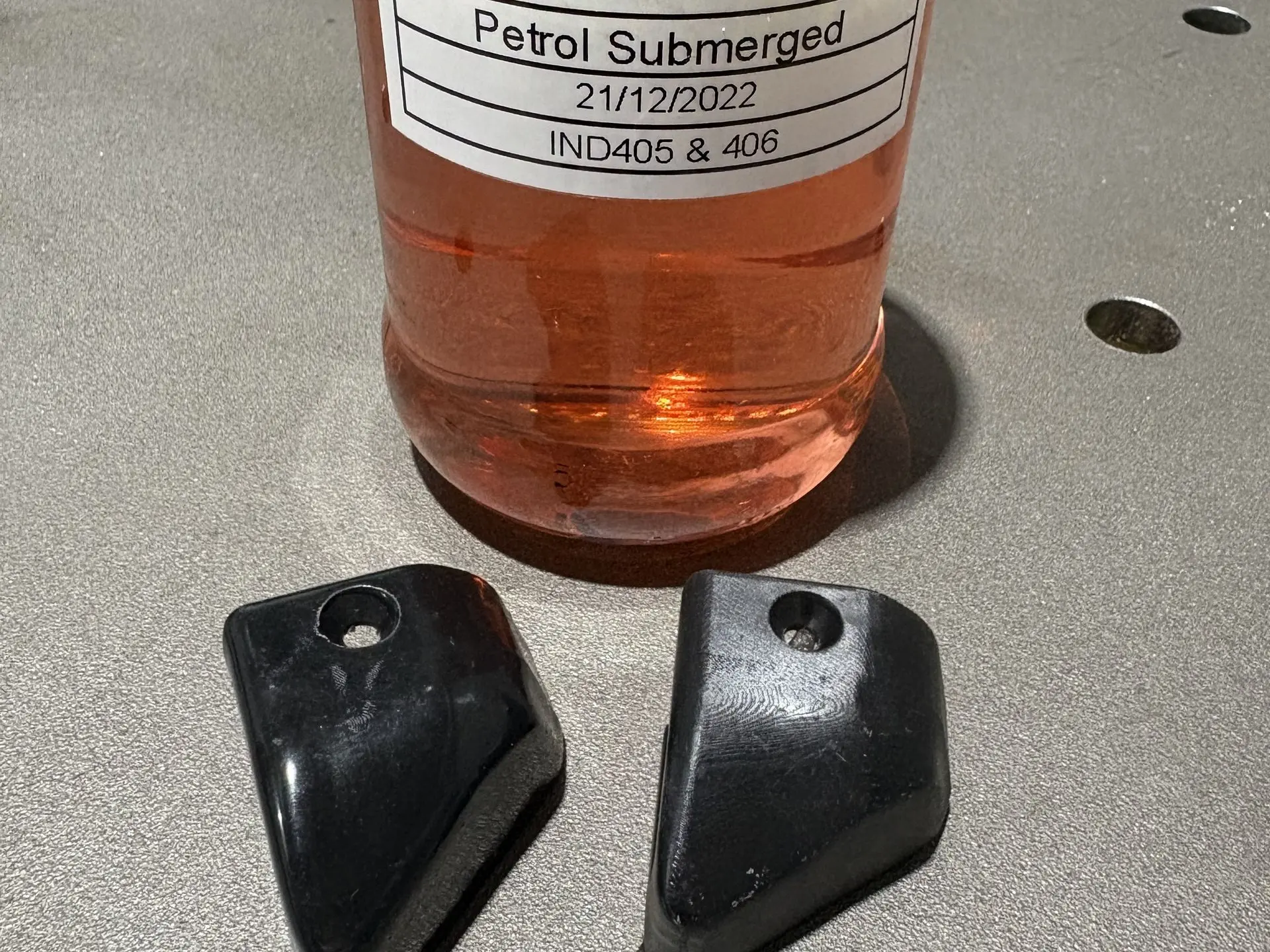

Chemical Resistance on components printed from LOCTITE® IND405 & IND406

Aluminium extrusion caps printed in IND405 and IND406, showing zero damage after being submerged in petrol since December 2022.

YOUR PATH TO PRODUCTION

Purchase Print-Ready Resins

We stock print-ready LOCTITE® resins for nationwide shipment. If you know what you need, head straight to the shop. If you're unsure, our Buyer's Guide will pinpoint the exact material for your project.

Use the Buyer's Guide Shop All Resins

Partner with IEE

Leverage our expertise. We design, print, and supply tough, high-performance components using Loctite engineering resins. Get flexible production without tooling delays for short runs, end-use parts, or custom components.

Contact Our Engineers