Pushing the Limits of 3D Scan Resolution

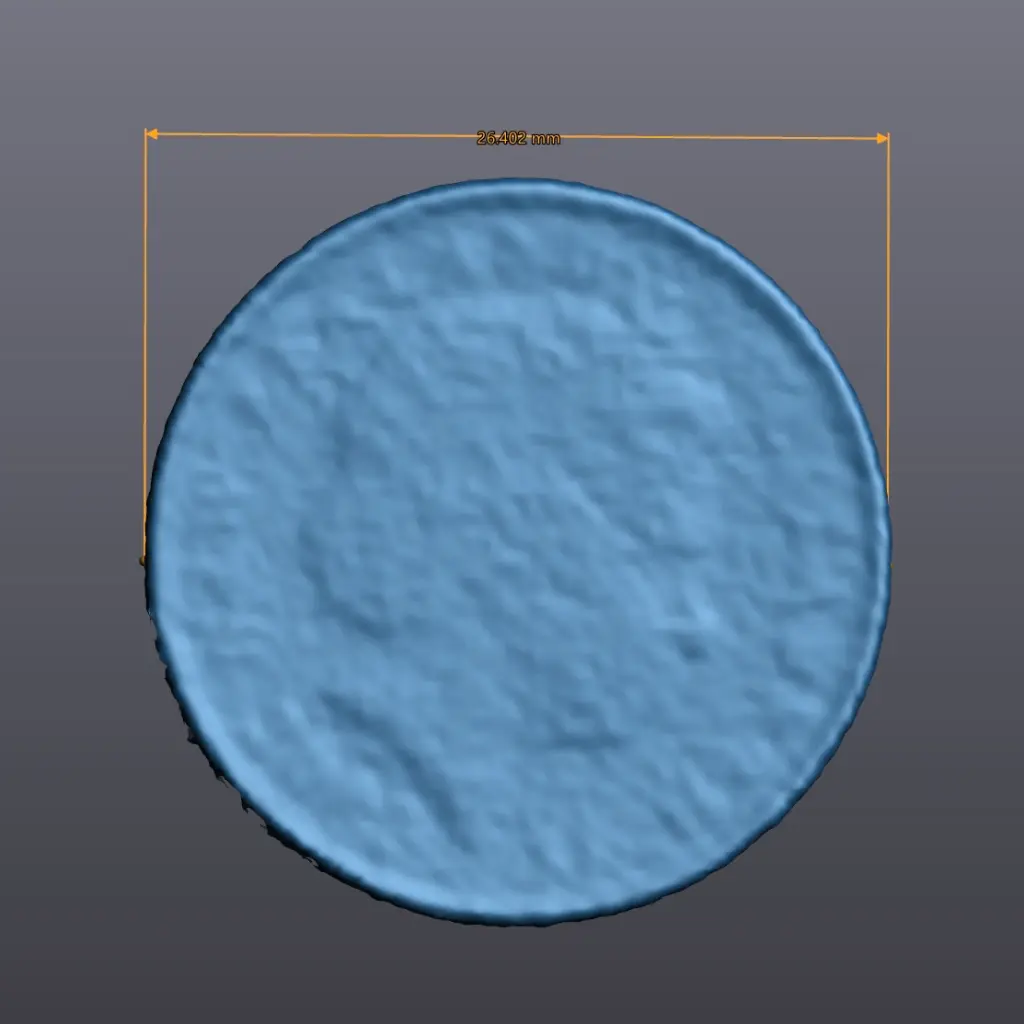

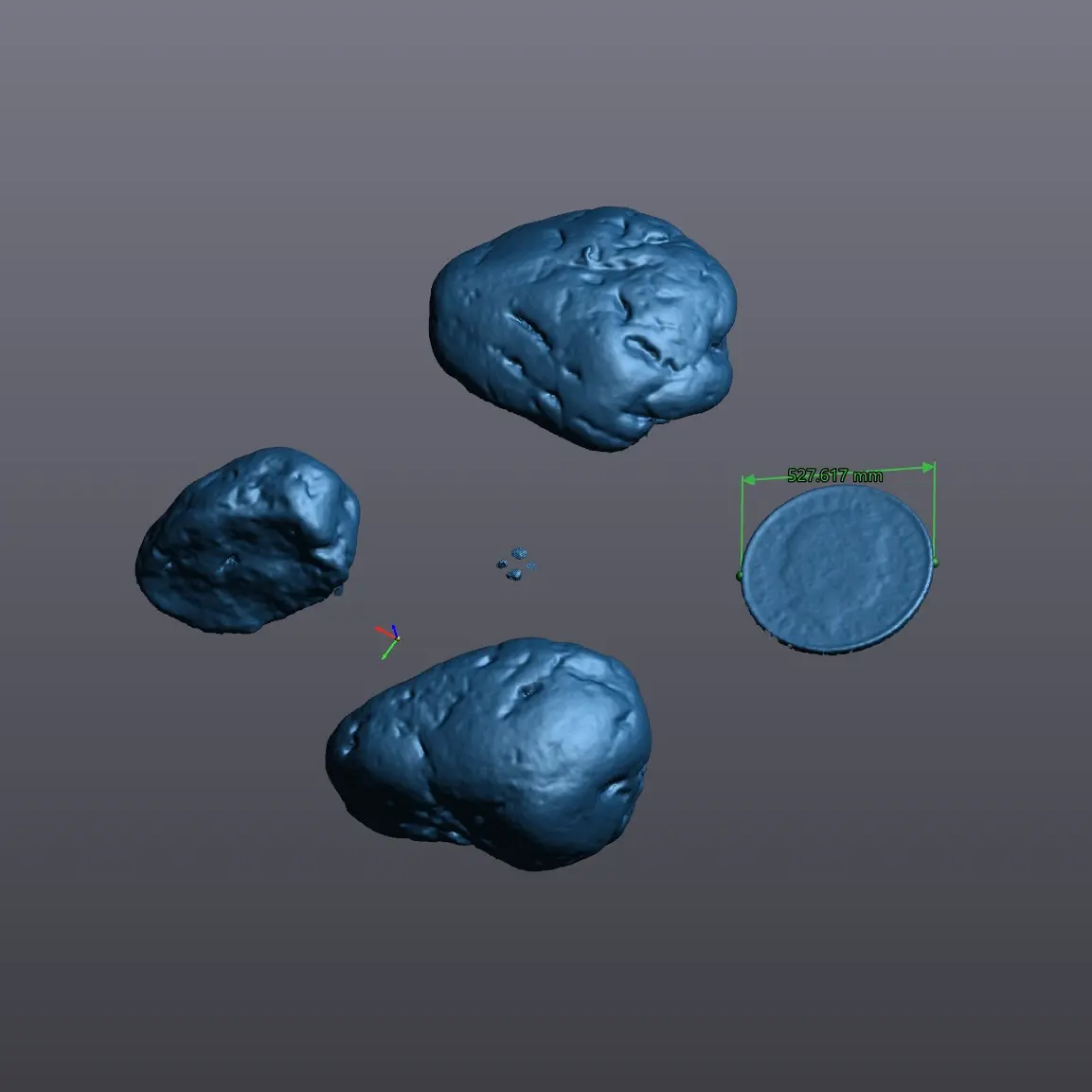

One of the most common questions we receive is: “How much fine detail can you capture with 3D scanning?” To demonstrate the level of resolution achievable, we scanned a New Zealand two-dollar coin measuring in at 26.40mm in diameter alongside three small stones with intricate surface details. The two-dollar coin serves as a familiar reference point, allowing you to easily compare scan resolution to a well-known object.

Understanding 3D Scanning Accuracy and Limitations

Precision in 3D scanning is crucial, whether for reverse engineering, quality control, or part reproduction. While high-resolution scanning can capture impressive levels of detail, there are inherent limitations based on the technology and the size of the features being scanned. This demonstration is to showcase what our in-house Creaform HandyScan 700 Silver Edition can achieve in terms of capturing fine details on whats generally considered as very small objects for handheld 3D Scanners.

Testing 3D Scanner Resolution with a Coin and Stones

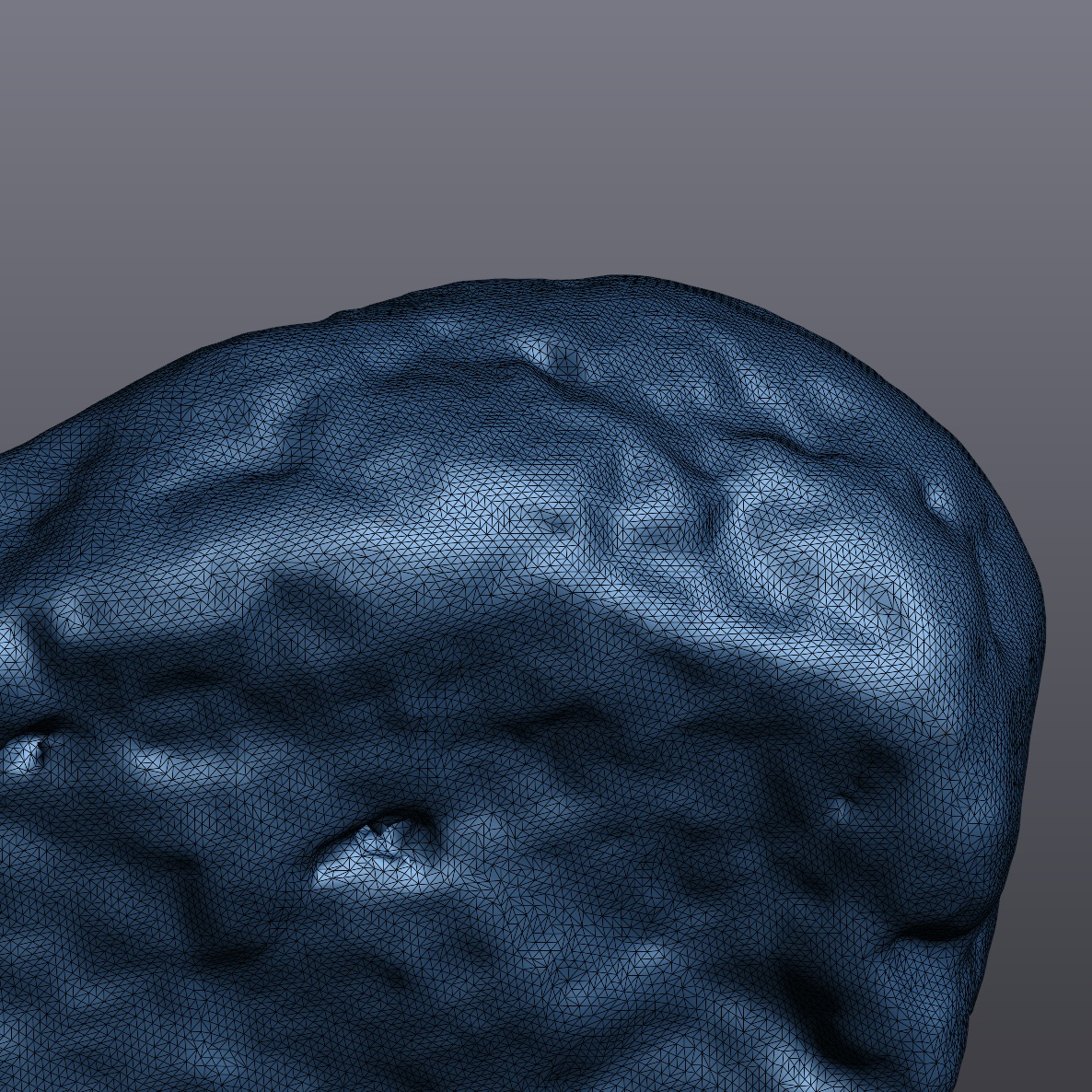

• 3D Scanner Used – The Creaform HandyScan 700 Silver Edition, with a maximum mesh resolution of 0.2mm (edge length of triangles in the scan).

• Scan Settings – For this demonstration, we scanned at 0.2mm resolution, the highest setting available for this scanner. In typical projects, we often use 0.4mm - 0.8mm resolution for parts under 150mm that require moderate detail. For large industrial components like sheet metal panels, we use up to and over 5mm resolution, as fine detail is not always necessary.

• Testing Detail Resolution – The text on the two-dollar coin is approximately 0.15mm in depth. Since our maximum resolution is 0.2mm, the scanner could not fully capture the embossed text, as it falls below the resolution threshold. This showcases a key limitation - features smaller than the resolution setting may not be clearly defined.

Real-World Applications of High-Resolution Scanning

• While ultra-fine details (such as engraved text) may not always be captured perfectly, the scan still provides valuable data for various applications:

• Creating Fixtures & Holding Tools – The scanned data can be used to create perfectly fitting cradles or work-holding tools for machining or assembly.

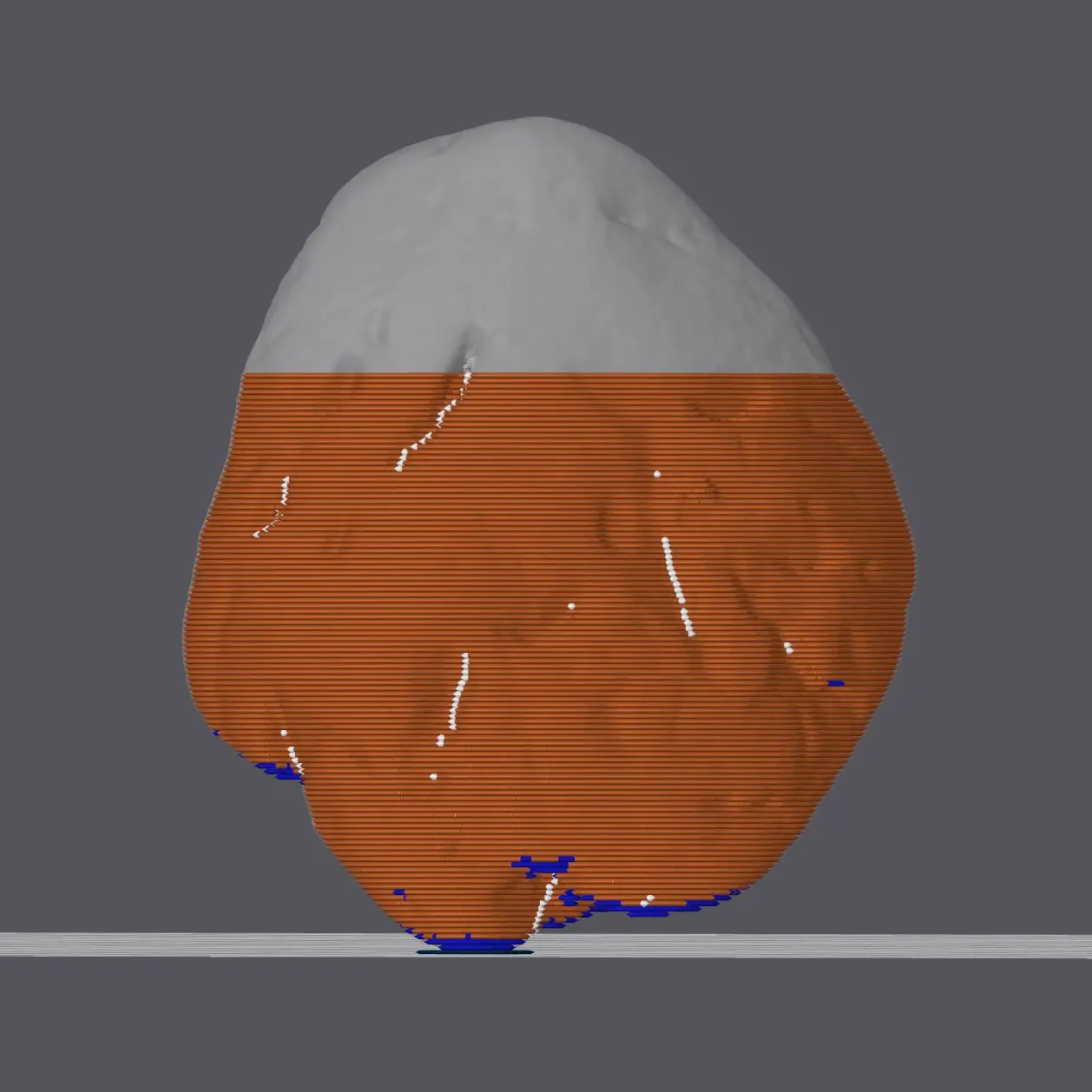

• Replication & 3D Printing – A watertight STL file can be generated for 3D printing, allowing for the creation of exact replicas for display models, spare parts, or scaled-up versions.

• Scaling & Modifications – Inside VxElements, the scan data can be scaled up to enhance details or adapted for other engineering purposes. One of many very useful tools inside the Creaform Software.

How Accurate 3D Scanning Benefits Our Clients

This example effectively demonstrates the precision limits of our 3D scanning capabilities. While the scanner cannot resolve details below 0.2mm, it still provides an accurate digital representation suitable for engineering applications, reproductions, and design modifications. For larger objects or less detailed parts, lower resolutions can be used to optimize file sizes and processing times.

Need High-Resolution 3D Scanning? Let’s Talk!

If you need high-accuracy 3D scanning for reverse engineering, quality control, or reproduction, we can help. Our in-house scanning and modeling services ensure precision and efficiency tailored to your project needs. Contact us today to discuss your scanning requirements!

Frequently asked questions

Here are some common questions about 3D Scanning.

It depends on the scanner’s resolution. Our Creaform HandyScan 700 Silver Edition can capture details as small as 0.2mm. Features smaller than this, such as fine text on a coin, carving or any artifact, may not be fully defined in the scan.

For objects under 150mm, we typically scan at 0.4mm - 0.8mm resolution for a balance of detail and efficiency. If ultra-fine details are required, 0.2mm resolution is the highest setting available on our scanner. For Larger parts up to 4m in length where no fine detail is required we can scan at the lowest resolution of 10mm.

Yes, we can generate watertight STL files from scan data, which can be used directly for 3D printing. The quality of the printed part is determined by the printer capabilities an of course highly dependent on the 3D Scanned items geometry. If it can be scanned, that doesn't mean it should be printed! every object is unique and consideration about the orientation should be taken before printing.

While high-resolution scanning captures fine surface details, it has limits—features smaller than 0.2mm may not be fully captured. Additionally, higher resolution scans create larger files sizes in the GB range, which can slow down your workstation and also be unnecessary for larger objects.

Industries such as manufacturing, engineering, quality control, product design, and heritage preservation all benefit from accurate 3D scan data for reverse engineering, toolmaking, and part replication.

If fine details matter (such as text or engravings), 0.2mm resolution is ideal. For Medium size parts 0.4mm - 0.6mm resolution is really good place to be, For larger parts, we recommend anywhere between 0.8mm to 5mm resolution to keep file sizes manageable while still capturing necessary details. Contact us, and we’ll help you choose the best settings!