Solving the cracked corner issue

When a local customer discovered structural cracks in the rear corners of their caravan, they needed a durable and cost-effective solution. Traditional repair methods like fiberglass patches or bogging lacked flexibility, risking further damage over time. Using 3D scanning and additive manufacturing, we engineered a custom cap solution to strengthen the caravan’s structure while allowing for necessary movement.

How damaged was the Caravan Body?

The customer recently purchased a caravan for camping trips but overlooked hidden structural issues, including significant cracks where the roof meets the rear window face. These large-radius corners are a common weak point in caravan bodies. A local repair shop recommended sanding everything back and fabricating a cap to reinforce the area. Typically, such repairs involve fiberglass, but cracks generally re appear in these caravan designs as there is no give for the body to flex, therefore requiring a more flexible, adaptable approach.

Fiberglass body crack repair

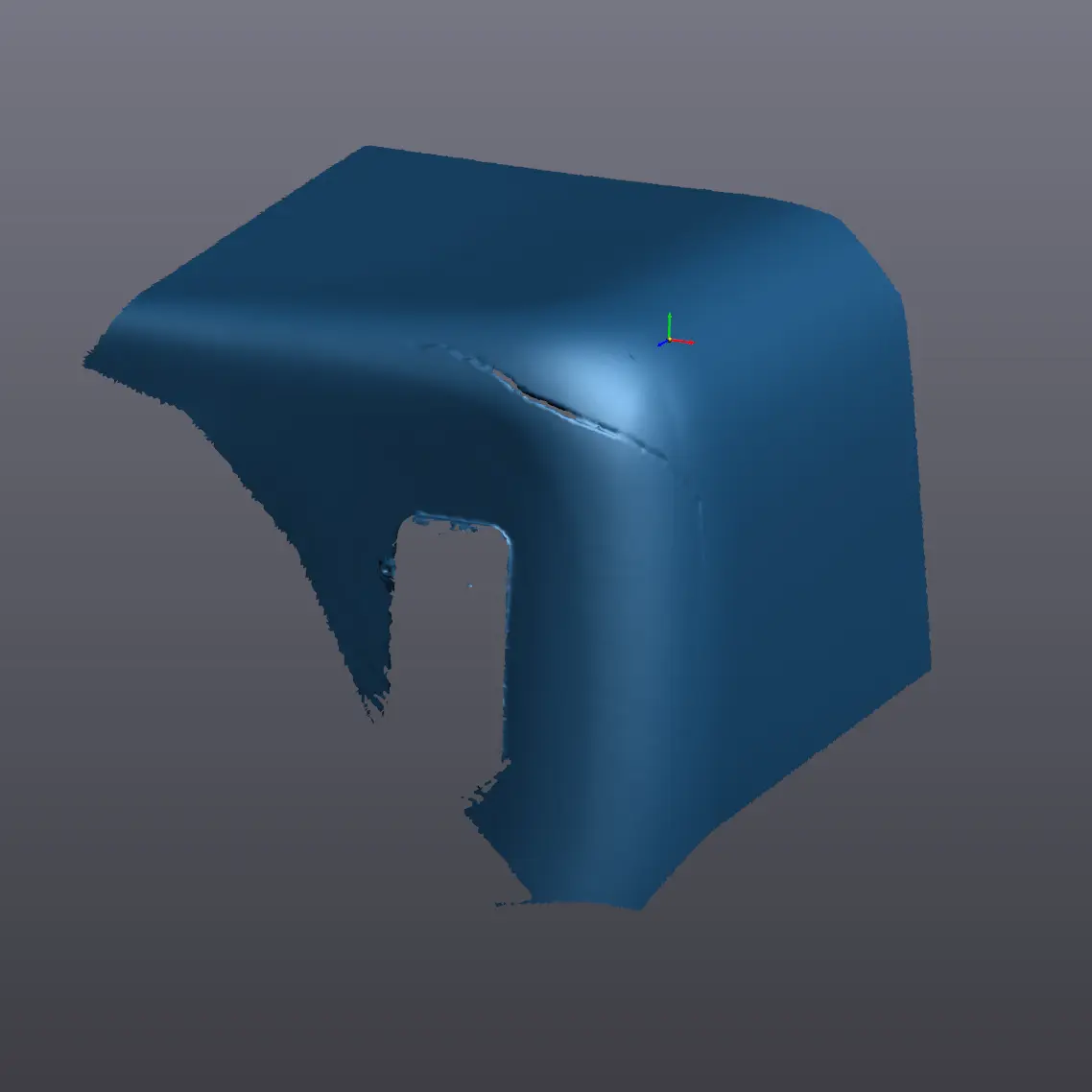

- 3D Scanning the Damaged Area: We used our Creaform HandyScan 700 to precisely scan the cracked sections of the caravan’s rear corners.

- The scan data was processed in Creaform VXmodel software to extract a clean surface profile for designing the replacement caps.

Generating the CAD Model

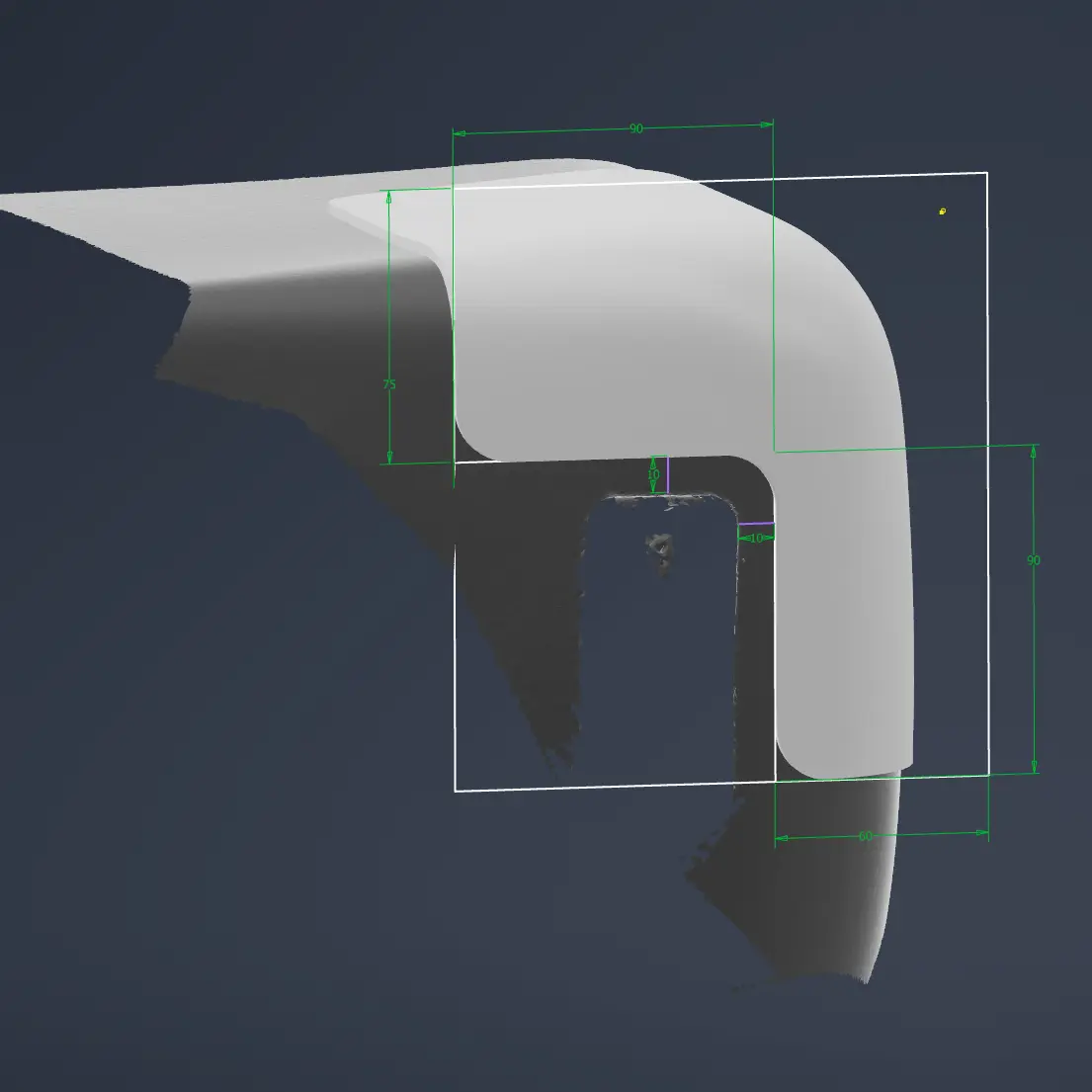

- The surface data was imported into an Autodesk Inventor IPT file.

- A 3D model was created with additional margin beyond the cracks for better reinforcement.

Material Selection & Printing Orientation

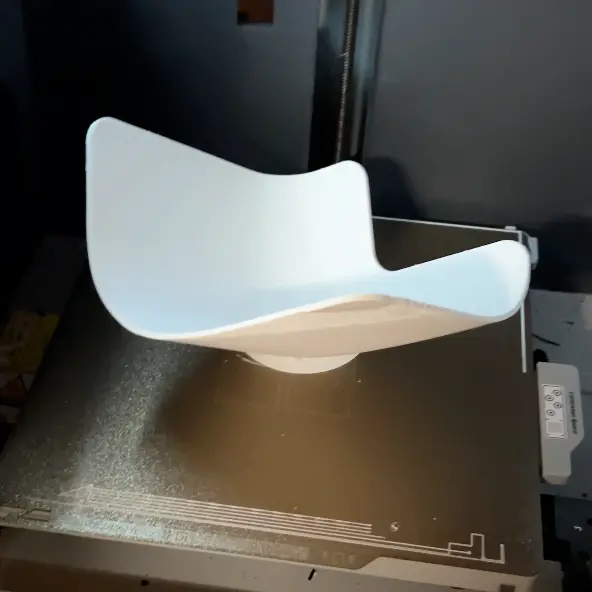

- We chose white PETG for its durability and flexibility, ensuring structural integrity without making the repair too rigid.

- The part was 3D printed with full infill to maximize strength & was printed vertically to produce the best finish.

Final Production & Installation

- The CAD Generate support structure on the printed cap was sanded completely off.

- The caravan body was primed and prepped before applying adhesive to bond the caps securely.

- Additional sealant was applied around the edges of the cap to body to ensure a watertight seal.

- Once the full caravan body repairs were completed, the entire section was repainted for a flawless finish.

Results: A Strong, Flexible Repair

This 3D-printed solution offers significant advantages over conventional fiberglass or bogging methods:

- Structural Support Without Rigidity – The cap strengthens the area while allowing slight movement, preventing future stress fractures.

- Custom Fit & High Precision – The 3D scanning process ensured an exact match to the caravan’s contours.

- Cost-Effective & Long-Lasting – A affordable option compared to fiberglass work, while offering a durable fix.

While all repairs have a lifespan, this solution effectively prolongs further cracking and allows the caravan owner to continue enjoying trips without worrying about immediate structural failures.

Do you have a unique repair challenge, we can engineer a tailored solution using advanced 3D scanning, CAD, and printing technologies. Contact us today to discuss how we can help restore and reinforce your caravan or motorhome.

Caravan corners often crack due to structural stress and body flexing over time. Traditional fiberglass repairs can be too rigid, leading to further cracking. Using a flexible yet strong 3D-printed cap reinforces the area while allowing movement, preventing future damage.

3D scanning captures the exact shape of the damaged area, ensuring a perfect fit for the replacement cap. This eliminates guesswork and allows for precise reinforcement without excessive modification to the caravan body.

PETG among others is an ideal material due to its durability, flexibility, and resistance to weather conditions. Unlike harder brittle plastics or rigid fiberglass, PETG allows for slight movement, preventing stress fractures.

A properly designed and installed 3D-printed repair can last as long as fiberglass patches, if not longer, due to its ability to flex with the caravan’s movement. Proper sealing and bonding are crucial to maximize longevity.

Yes! Since each cap is custom-designed from 3D scan data, we can create solutions for various caravan makes and models, ensuring a precise and effective fit.

The cost depends on the size and complexity of the repair, but it is often comparable to traditional fiberglass work. Contact us for a personalized quote based on your caravan’s damage.

Frequently asked questions

Here are some common questions about these projects.