This post give a quick glimpse of the process involved to adapting a more modern gearbox to and old engine.

Note : In this particular job the client chose the gearboxes and asked just for an adapter flange to be designed and nothing else. they took care of everything else.

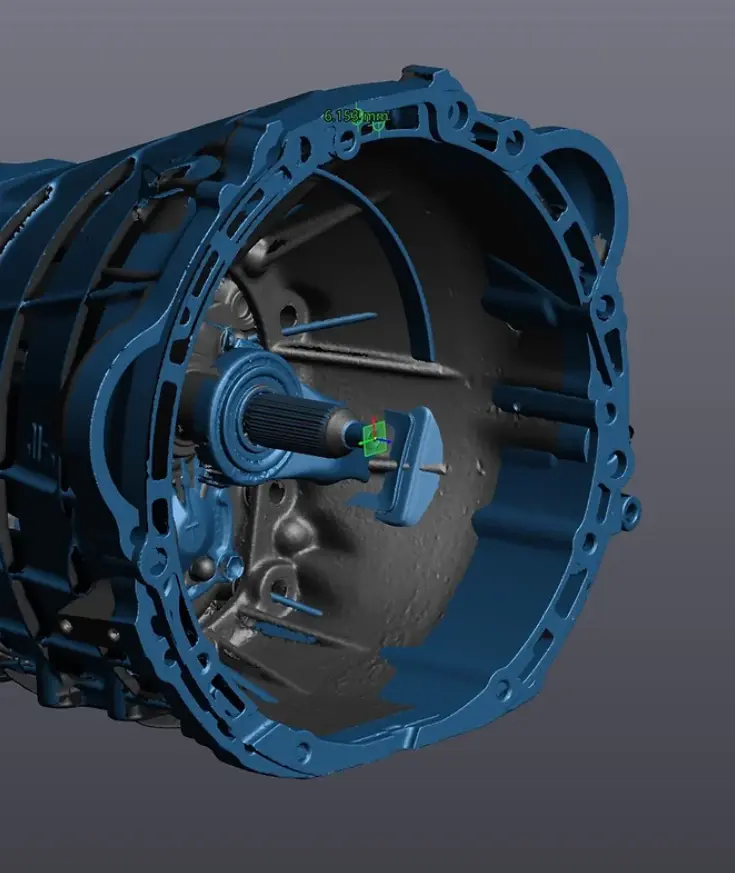

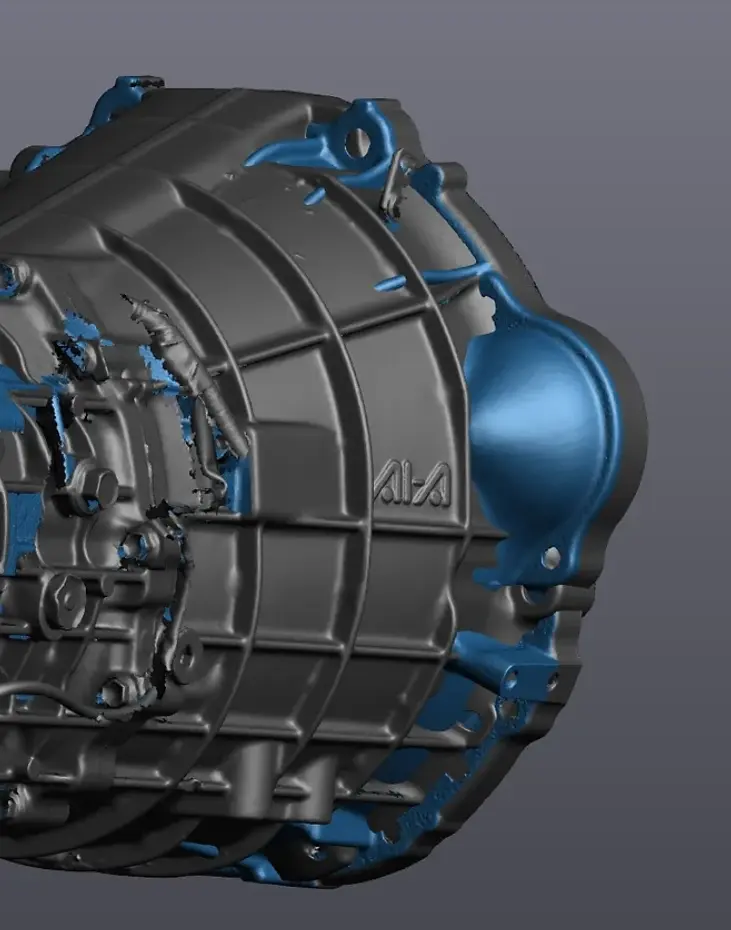

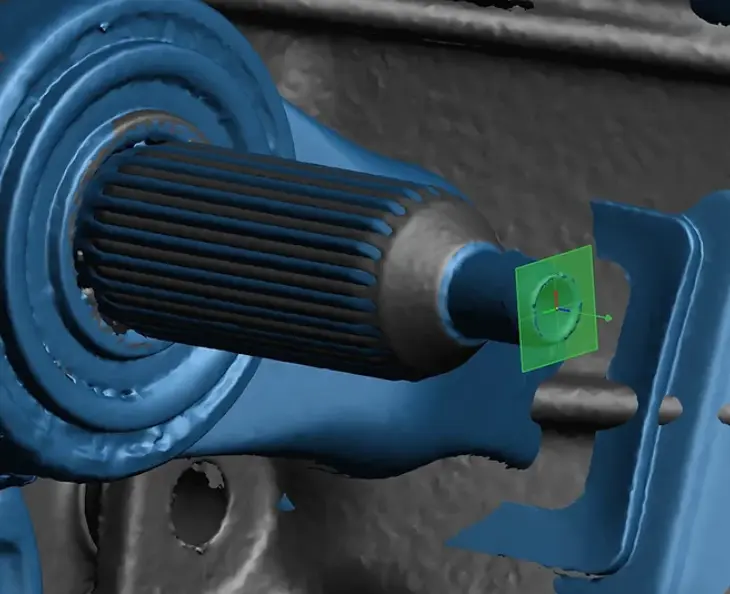

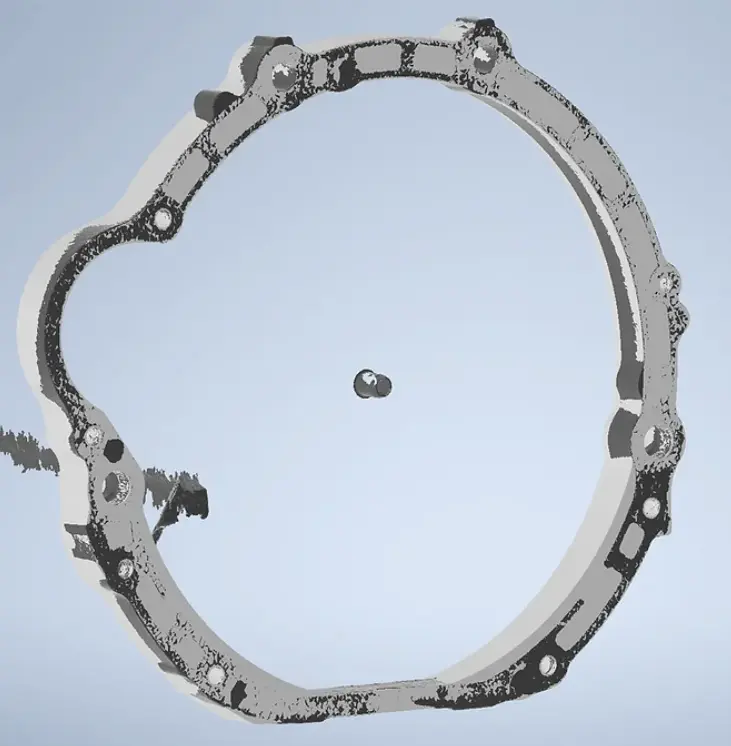

3D Scans of both the old 5 Speed Transmission & The newer more modern 6 Speed Transmission were acquired

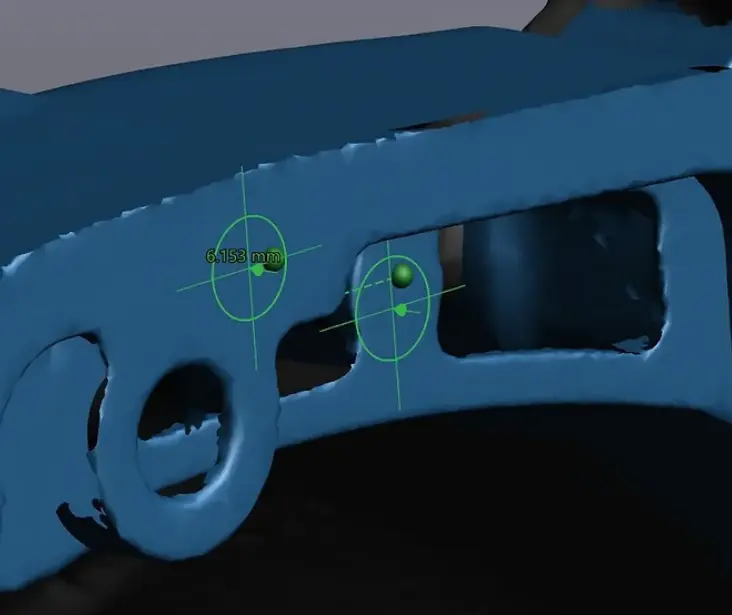

After carefully assessing the important points and deciding on a workflow, we got into it, both scan files were cleaned up, we then aligned and set an origin point for both Transmissions, In this instance, we needed 1 main relationship, The Input shafts happen to be identical so these were mated in the same location.

The flange depth difference was around 6mm so in order to get the input shafts in the correct location we measured the heigh difference, the client requested he runs a 25mm flange thickness so therefore in total the new Gearbox bell-housing will be machined back 31mm to make sure when the new flange is put in place and welded it will sit at the correct depth to ensure the input shaft seats correctly in the spigot bearing in the back of the crankshaft.

Overlay of the new flange with the 3D Scan Data