For Nissan Skyline R33 GT-R owners, finding replacement parts for older models can be a real challenge. We recently tackled a project where a customer from Tauranga, New Zealand, faced this exact problem. He needed a rear spat bracket – a small steel bracket that allows you to fit the body kit part to the rear bumper area – for his R33 GT-R. The issue? The original part was no longer manufactured or avaiable anywhere.

The Original Part's Complex Design

The original rear spat body kit part was made from sheet metal, stamped into shape. This stamping was necessary because it featured two bends that are extremely close to each other. Folding such a design consistently with standard machinery is exceptionally difficult, often requiring job specific tooling. This complexity is why these parts were typically stamped, meaning expensive forming tools would be needed for new production.

Our Reverse Engineering Process

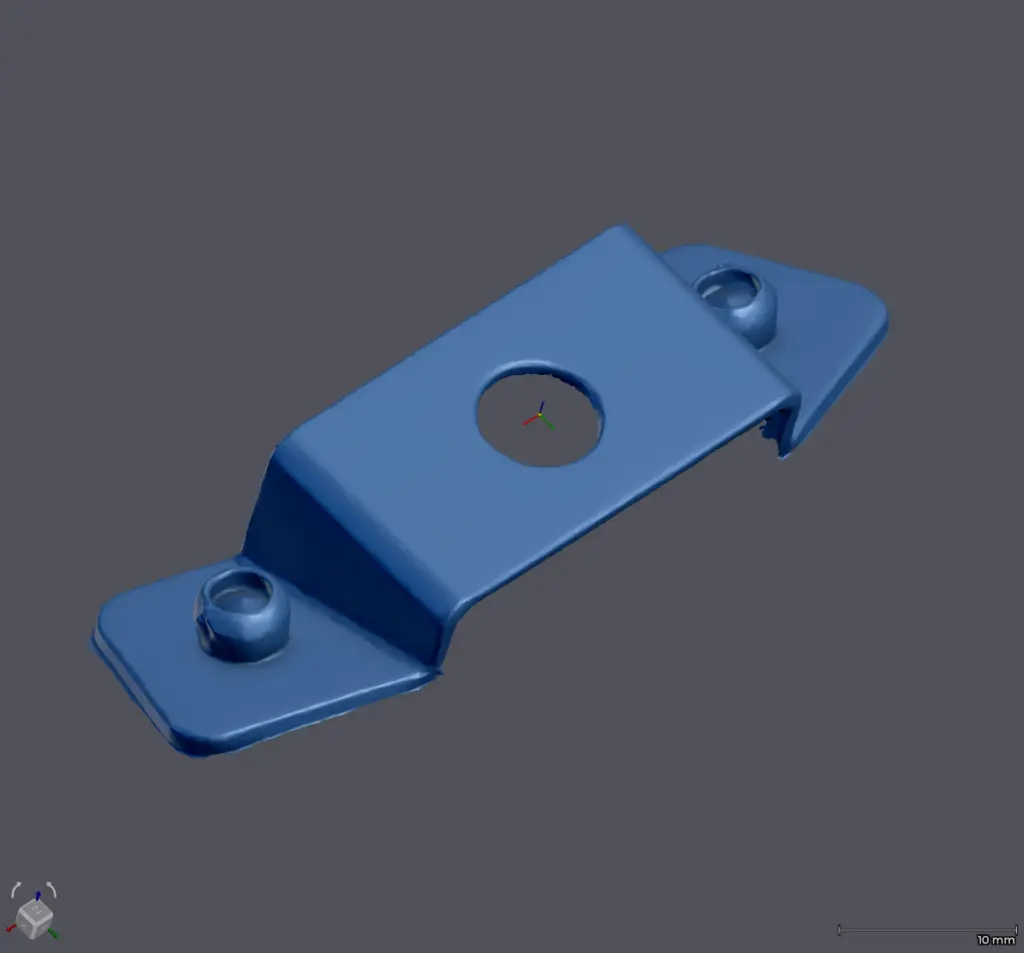

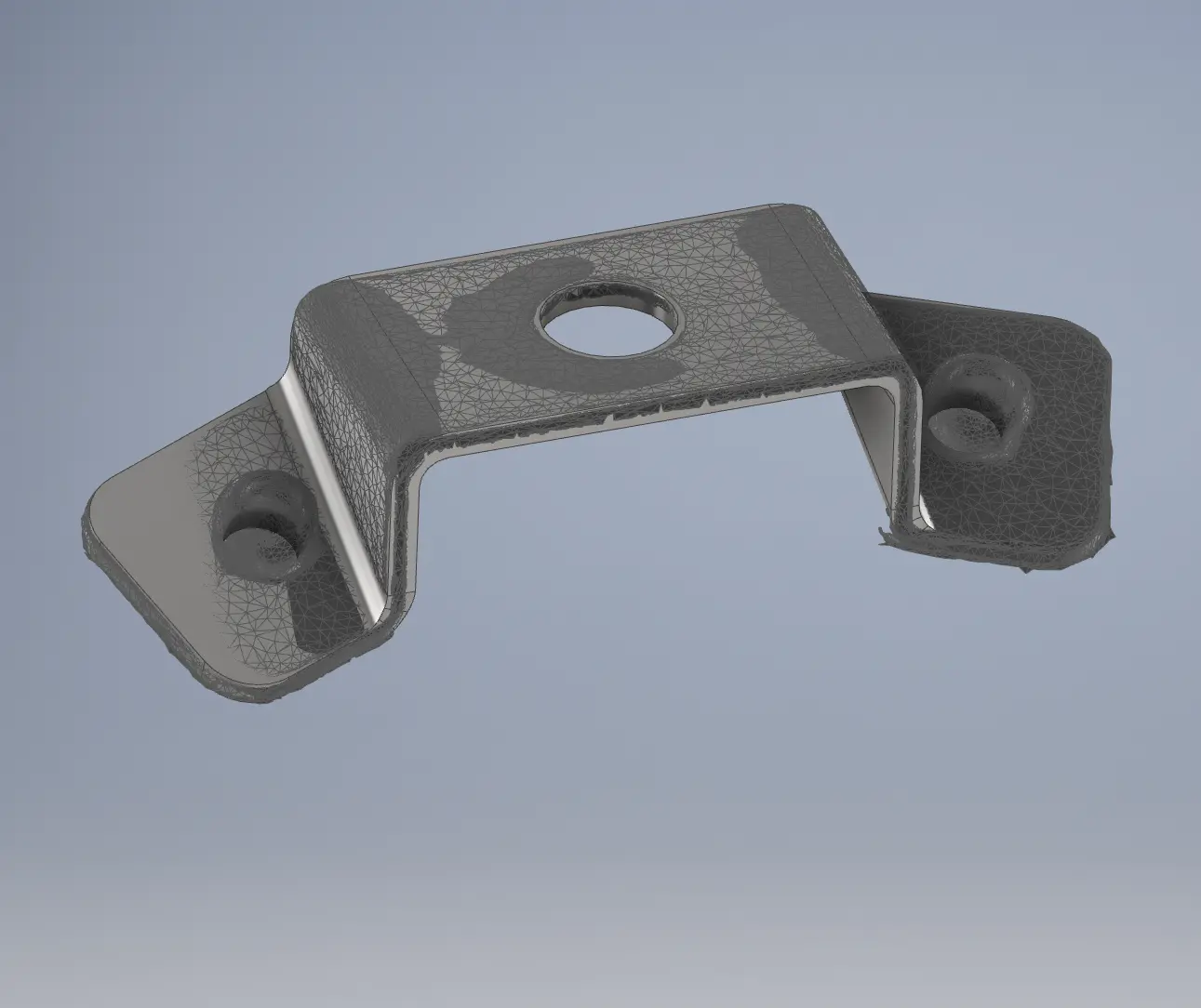

To address the customer's need for this unavailable part, we started by acquiring the existing piece. Our first step was to 3D scan it using our in-house Creaform HandyScan 700. This process gave us a highly-detailed digital copy of the part. After the scan, we performed a basic alignment of the origin point within the Creaform OS scanning software. From there, we exported the data to Autodesk Inventor, where we completed the reverse engineering process to create a new 3D CAD model. We always include a visual confirmation step, overlaying the scan data with our new CAD model to confirm we are within a tolerance of plus or minus 0.1mm. This is done inside Creaform OS Inspection module where we can analyse 3D data and detect deviations.

Initial Manufacturing and Its Limitations

Once we had the accurate CAD model, we initially had the part manufactured locally for the customer. The goal was to get the parts into his hands as quickly as possible so he could get his car back on the road. We had the parts waterjet cut from stainless steel and then folded. The customer was able to pickup these parts directly from the fabrication shop, and within a few days, he had them ready to fit. He was able to reinstall the stainless steel brackets onto his spat body kit part using new pop rivets and then refit the entire assembly to his Skyline.

While this initial method worked, we realized that manufacturing these specific pieces from sheet metal wasn't ideal for ongoing production. The two very close folds still presented a challenge, making consistent production difficult without specialized tools & jigs.

The Power of Metal 3D Printing

We then explored other manufacturing avenues and found the next best solution: metal 3D printing. This method completely sidesteps the issues presented by the close bends. With stainless steel 3D metal printing, we can achieve a beautiful finish on the part, and the complex geometry of those two bends no longer presents a manufacturing limitation.

Now, we manufacture these Nissan Skyline R33 GT-R spat body kit brackets using stainless steel 3D metal printing. This allows us to provide a direct replacement for these once-unavailable parts from Nissan. If you're a customer with a broken or rusted out set of these parts currently installed on your vehicle, we now offer a reliable and high-quality solution.

If you're struggling to find replacement automotive parts or need a custom manufacturing solution for your vehicle, reach out to us. We specialize in 3D scanning, reverse engineering, and custom 3D printing services for unavailable components.

Frequently Asked Questions

Here are some common questions about our RB26 Thermostat Housing Titanium Stud Kit.

The original parts were stamped from sheet metal using specialized tooling back in the day. Since Nissan no longer manufactures them becuase demand is so small, and stamping tools are expensive to keep or reproduce, genuine replacements are no longer available.

Our process involves 3D scanning the original part and reverse engineering it in CAD, ensuring accuracy within ±0.1mm. This guarantees a precise fit.

We manufacture the brackets from stainless steel 316 using metal 3D printing. This provides excellent strength, durability, and resistance to rust.

The brackets are a direct replacement. They attach to the body kit part using two pop rivets, just like the originals, and fit back onto the rear bumper area without modification.

While sheet metal worked for one-off prototypes, the close folds in the design made production difficult and companies will refuse to produce the parts. Metal 3D printing avoids these issues and delivers a stronger, more reliable part.

Yes. We specialize in 3D scanning, reverse engineering, and custom manufacturing solutions. If you can supply an original sample (even damaged or the opposite side), we can usually reproduce it.